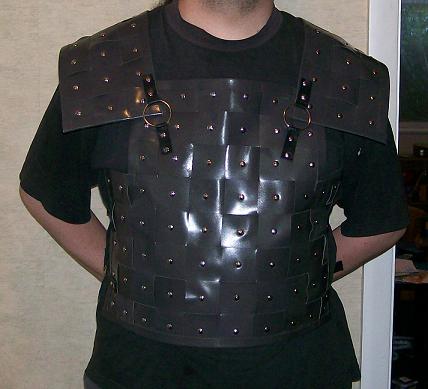

A while ago when browsing larp gear stores I came across woven corsair armour - basically studded leather made out of leather strips woven together and riveted. Which seemed like a good and fairly cheap idea, especially if you picked up leather dirt cheap on TradeMe.

Now Kingdom has given me an excuse to make some. The raw material is 0.8mm calfskins ($20 for five, which should be enough for one set). This is obviously too thin for real armour, but it’ll look the part, which is what’s important. A full suit (front, back and two shoulders) will need about 250 rivets (6mm single caps are about $3 per hundred at GDL). Which leaves closures and fittings - the sides could be buckled or laced; the shoulders probably need to be fixed in some way at the back, and either buckled or laced at the front (assuming you want to be able to get into the stuff without assistance). Total cost: $30 - $40 for a set, plus time. Required tools: craft knife, metal ruler, leather punch, hammer and rivet setter.

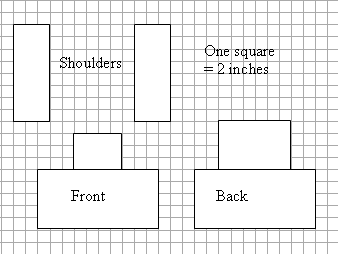

Stage one was measuring the victim and making a pattern to see if it would work:

I’d decided to use two-inch wide strips, so it was a matter of measuring the widest point on the torso, and coming up with a number close to that which was divisible by two (I went slightly smaller, on the basis that the lacing gave some wiggle room; remember to measure over the sort of stuff the victim will be wearing under it). Waist to armpit minus an inch gave me the big rectangle for the front and back, and waist to neck minus a bit gave me the height of the small rectangle for the front. The back is just one strip wider and higher. Testing with paper showed the wearer would be able to move properly - always useful.

Stage two was to test the construction method by making a shoulder:

This took me about an hour, from deciding I wanted to do it, wibbling around a lot, drawing and cutting the strips, making a template to get the holes in the right place and finding my rivets. One thing which became apparent was that I needed to make the strips a bit longer, as the weaving used up some of their length. Fortunately, its something I can hide when I edge it. The next shoulder will probably take half that long, as some of the strips are already drawn up for it. Based on that, I think the construction time for a whole set will be ~five hours to get all the bits cut out, woven and riveted.

Stage three will be prettying it up. I’m planning on edging the shoulders, with a half-inch border on each side. That will be time-consuming, as it will require stitching and hole punching. If I’m in a hurry, I can skip this step, or use glue and go back to it later.

Stage four will be putting it all together with lacing and/or buckles. Which should take less than an hour.